Look inside…the pilot plant

The place to be for bacteria

In the ‘Look inside…!’ series, we again spotlight another Winclove team and zoom in on their work. This time: our lab colleagues in the pilot plant.

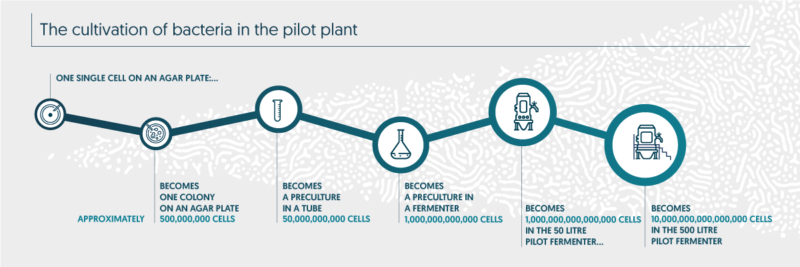

Our R&D department is at the heart of all Winclove Probiotics’ research. Research that is crucial for not only the quality, safety and effectiveness of our formulations, but also the development of impactful microbiota-management premium products. And our new fermentation pilot plant is vital to these core efforts: it’s where we grow one miniscule cell into as much as 400 litres of bacterial culture. And this activity in turn generates a cascade of science on our bacterial strains, both current and new.

Eye-catcher

In a few years Winclove Probiotics is moving to a new building, with a truly eye-catching lab / production area. Instead of just sitting back and waiting for our bright, shiny future, we decided to deploy the brand new fermentation equipment in a new pilot plant at our current location.

Growing pains

This gives us the opportunity to deal with the growing pains in the equipment and processes before we move to the new building’, explains Wout Wolken, senior fermentation specialist at Winclove. ‘We also educate colleagues, write protocols and research new food-grade [fit for human consumption, Ed.] ingredients. And of course we contribute to running projects, like expanding our strain database with new unique strains and gathering even more valuable knowledge on our current strains.’

Fermenting?

Wout explains: ‘Traditional fermentation is usually about the processing of microorganisms on a medium, the chosen breeding ground. For example, perishable milk changes into long-life cheese. Whereas for us, it’s really all about the microorganisms themselves, so we remove the used growing medium from the bacterial culture and the bacteria remain.’

In control

Moreover, for traditional fermentations the controls are quite limited, whereas in the pilot plant we can regulate the steps tightly. The work is done with great care and according to stringent hygiene protocols. ‘To put it briefly, we create the most optimal environment possible for bacteria to be able to grow’, says Wout. ‘This is a multifactorial complex process.’

Optimal growing medium

Wout: ‘Prior to the fermentation, extensive work is often done in the lab to find the right composition for an optimal growing medium for the various bacterial strains.’ The optimum growth medium may vary per bacterial strain. In the ‘medium brewery’ the food-grade ingredients are then weighed and dissolved. The resulting preculture of roughly 300 millilitres is sterilely transferred to the BioTwin, our tower fermenter that then yields the first fermentation, up to roughly 40 litres of bacteria culture.

Up to 400 litres

All the conditions vital to successful fermentation are monitored closely, for example by measurement and sterile sampling of temperature, acidity, oxygen levels and the chosen medium. Wout: ‘In the BioPilot a second fermentation takes place: the culture grows to about 400 litres. Then we remove the growing medium and freeze-dry and grind the bacteria to a powder. The various powders, bacterial strains, are eventually mixed to make effective premium probiotic formulations.’

Expanding the strain database

Currently in Winclove Probiotics strain database, each strain has specific properties that favourably affects different aspects of health. ‘But of course we’re continually searching for new, useful bacterial properties to further enrich our product portfolio’, says Wout.

Research and knowledge sharing

‘In the pilot plant we can do sustainable, effective and efficient research into potentially new strains’, adds Wout. ‘In this way we can for example run small batches for trials or completely new probiotic formulations for which we don’t know yet when the demand for large scale production will be large enough.’ This we do to further develop the synergy with our strategic alliances, and the knowledge we generate through our pilot plant work we can for example share with external strain providers; Wout and his team basically invented strain cultivation processes that the suppliers could take over. This not only improves products and processes, but it strengthens our collaboration with external strain providers. The collective goal together with our trusted business partners: helping more people worldwide through impactful premium probiotics.

Interesting updates in your mailbox

Subscribe to our newsletter and receive the latest news about Winclove, probiotic-related research & publications, relevant market developments and inspiring articles.